|

|

|

The ignition coil is a transformer. It transforms the car's 12 volts to many thousands of volts. It is firmly fixed to the engine or cars body under the bonnet. The clamp holding the coil must be clean and tight with a good electrical contact to metal surfaces. Inside the casing there is two coils of wire, the 12 volt wire is wound about 120~200 times around a thinner wire that is wound 20,000~120,000 times around an metal centre core. When connected to an electric circuit a strong magnetic field is concentrated around the coils, when the electricity is interrupted the magnetic field collapses inducing itself from one set of coils into the other set of coils. As we want to increase the voltage our battery voltage is connected to the lesser number of turns and the high tension (spark plug) leads are connected to the higher number of turns of wire. As the lesser number of coils field induces into the many, many turns of the other, the voltage is multiplied over and over again, causing the sharp rise in voltage necessary to jump the plug gap. The plastic tower on top of the coil forms the insulator that stops the high voltage sparks from leaking into the car's body. The Ignition coil must be clean and free of damage.

The ignition coil is a transformer. It transforms the car's 12 volts to many thousands of volts. It is firmly fixed to the engine or cars body under the bonnet. The clamp holding the coil must be clean and tight with a good electrical contact to metal surfaces. Inside the casing there is two coils of wire, the 12 volt wire is wound about 120~200 times around a thinner wire that is wound 20,000~120,000 times around an metal centre core. When connected to an electric circuit a strong magnetic field is concentrated around the coils, when the electricity is interrupted the magnetic field collapses inducing itself from one set of coils into the other set of coils. As we want to increase the voltage our battery voltage is connected to the lesser number of turns and the high tension (spark plug) leads are connected to the higher number of turns of wire. As the lesser number of coils field induces into the many, many turns of the other, the voltage is multiplied over and over again, causing the sharp rise in voltage necessary to jump the plug gap. The plastic tower on top of the coil forms the insulator that stops the high voltage sparks from leaking into the car's body. The Ignition coil must be clean and free of damage.

If you suspect a fuel or ignition problem, look closely at the firing end of spark plugs under a strong light, particularly right down inside the edges alongside the centre electrode. The different deposits can help diagnose the problem.

There are three basic indicators when looking at spark plugs:

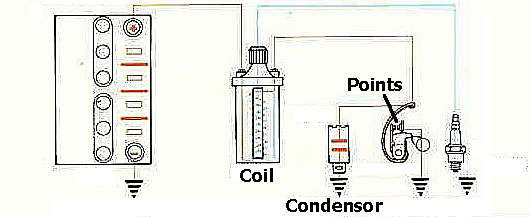

The ignition distributors is about the size of a can of beans with a plastic cap with thick leads running from the top of it across to the spark plugs. Older type cars have a basic distributor containing ignition contact points and a rotating shaft with a cam lobe for each cylinder. As the engine rotates so does the cam lobe, which pushes the contact points open, interrupting the flow of current in the ignition coil. This is the trigger that interrupts the coil circuit causing the high voltage spark. The high voltage has an unwanted effect which causes the current flowing across the contact point to continue to flow, so a condenser is fitted to the circuit to soak-up the excess current, stopping the current flow as the points open. The distributor is connected to the coil by two circuits, a thin wire with low voltage at the contact points and high voltage lead from the coil tower to the centre post of the distributor cap. Apart from keeping the distributor cap clean and corrosion free, it requires only inspection when tuning the engine. Ignition points on the other hand need to be inspected, adjusted and replaced regularly to keep the engine running at it's best.

top

The ignition distributors is about the size of a can of beans with a plastic cap with thick leads running from the top of it across to the spark plugs. Older type cars have a basic distributor containing ignition contact points and a rotating shaft with a cam lobe for each cylinder. As the engine rotates so does the cam lobe, which pushes the contact points open, interrupting the flow of current in the ignition coil. This is the trigger that interrupts the coil circuit causing the high voltage spark. The high voltage has an unwanted effect which causes the current flowing across the contact point to continue to flow, so a condenser is fitted to the circuit to soak-up the excess current, stopping the current flow as the points open. The distributor is connected to the coil by two circuits, a thin wire with low voltage at the contact points and high voltage lead from the coil tower to the centre post of the distributor cap. Apart from keeping the distributor cap clean and corrosion free, it requires only inspection when tuning the engine. Ignition points on the other hand need to be inspected, adjusted and replaced regularly to keep the engine running at it's best.

top Electronic distributors don't have the same wearing parts as older points systems at the trigger device. And so do not require the same regular adjustment as points systems do. Electronic systems, once correctly timed are very reliable and relatively robust, and do not require further adjustment. Electronic systems are not easily diagnosed without specialised equipment. Because specialised equipment is needed to check electronic systems they are not servicable on the side of the road, usually requiring towing when they breakdown.

top

Electronic distributors don't have the same wearing parts as older points systems at the trigger device. And so do not require the same regular adjustment as points systems do. Electronic systems, once correctly timed are very reliable and relatively robust, and do not require further adjustment. Electronic systems are not easily diagnosed without specialised equipment. Because specialised equipment is needed to check electronic systems they are not servicable on the side of the road, usually requiring towing when they breakdown.

top